Building ventilation: Retrofits to reduce energy consumption and improve occupant comfort - by Casey Birmingham

February 16, 2016 - Construction Design & Engineering

Casey Birmingham, The Falcon Group

In recent years, building owners, managers and tenants have been proactive in reducing their building’s carbon footprint and reduce utility expenses. Popular projects in NYC include lighting retrofits, fuel conversions, boiler replacements, battery storage and occasionally renewables. While highly beneficial to the building, these projects typically involve high up-front capital expenditure from the building, resulting in missed savings opportunities. Furthermore, these projects may have an impact on the building’s energy consumption and bottom line, but they typically have a negligible impact on occupant comfort.

One area that is often overlooked and undervalued is the building’s ventilation system. The ventilation system is responsible for maintaining proper indoor air quality (IAQ) throughout the building. Its interaction with the building’s heating and cooling equipment is critical when maintaining occupant comfort. The ventilation system is also a large component of the building’s overall energy consumption, estimated at 15-25% for typical buildings in NYC. The large energy impact is primarily due to the increased load on the heating and cooling equipment to pre-treat outdoor air that enters the building. Testing, adjusting and balancing projects on antiquated ventilation systems can have huge impacts on a building’s energy performance.

Spaces are ventilated with mechanical equipment or by natural means through the use of operable windows. The NYC Building and Mechanical codes dictate the minimum requirements for both methods of ventilation. The minimum mechanical ventilation requirements have been reduced substantially in many spaces since the 1968 NYC Building Code was enacted. For example, under the 1968 building code, residential kitchens ventilated by mechanical means required two cubic ft. per minute (cfm) of exhaust air per s/f of kitchen space. This equates to ventilation rates ranging from 100-200 cfm. The 2014 mechanical code requires a minimum of 25 cfm of continuous exhaust for the same space.

The 2014 building code’s reduced ventilation requirements result in less air infiltration through the building envelope, lower heating and cooling loads and smaller, quieter exhaust fans. These improvements can have a huge impact on the building’s energy performance and utility costs.

The following scenario is typical of a NYC multifamily building, constructed prior to 1980. Kitchens and bathrooms that do not have any exterior windows have an exhaust grille, located near the ceiling. Exhaust is ducted to multiple fans on the roof that operate continuously. The airflow rates are likely to be unbalanced across the building and the grilles are likely filled with dust and debris from years of continuous operation. Average exhaust airflow from kitchens and bathrooms are 150 cfm and 50 cfm respectively, far above the minimum ventilation rates required by the 2014 mechanical code.

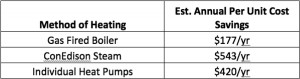

Table 1

The table provides estimated annual cost savings per residential unit for the building described in the scenario above. The savings will vary based on the heating and cooling systems within the building, as indicated in the table.

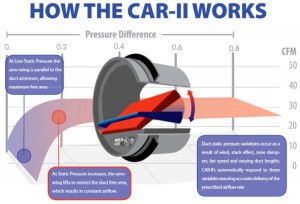

The primary concern when balancing a ventilation system is the effect that it will have on indoor air quality (IAQ) and occupant comfort. The majority of buildings with mechanical ventilation experience issues with uneven air distribution. When exhaust airflow rates are reduced, imbalances across the building may create backdrafts and other undesired effects. It is important that air exhaust registers are provided with constant volume airflow regulators (CARs). A CAR is provided with an automatic damper that maintains a relatively constant airflow, allowing for air balancing across the building. Installation of these devises will help ensure that each occupant has adequate ventilation during the retrofit project, improving their overall comfort.

Figure 1

There are additional comfort-related benefits to eliminating the excess exhaust in a building. Buildings with excessive exhaust are maintained in a negative pressure relative to outside, allowing air to rush into openings in the building envelope. The combination of stack effect and overventilation can be felt in the lobby of a tall building in the winter. Air rushes in on the ground floor, creating an uncomfortable environment for occupants. Reduced exhaust ventilation also results in less infiltration through window frames and other areas of a dwelling unit that may feel drafty.

Buildings older than ten years should have their ventilation system designs evaluated by a mechanical engineer with a working knowledge of the NYC mechanical code. Building owners without original building drawings or construction documents should have their ventilation system inspected with an airflow meter. The design professional can prepare a work scope to be implemented by a NEBB-certified air testing and balancing contractor. The resulting change in ventilation rates can be used to estimate the annual ongoing energy and cost savings resulting from the work.

Casey Birmingham is a senior project manager at The Falcon Group, New York, N.Y.