in compliance with OSHA standards and

upholding GMP/Quality control per client standards.

Rochester, NY Mitigating risk is at an all-time high in all genres of business. NY State Industrial Coatings (NICI) understands this and has the ability to ease client’s concerns by mitigating these risks by providing innovative solutions other companies in the industry cannot. The team at NICI takes great pride in embracing the projects that no one else can accomplish. Tight deadlines, complex coating systems, installation under adverse conditions with high degree of risk, are just a few of the challenges that NICI overcomes on a daily basis. This is where NICI has found it’s niche.

New York State Industrial Coatings, Inc.

New York State Industrial Coatings, Inc.

President and CEO, Jeff DeFranco, or “coach” as his team calls him, founded the company 30 years ago. Jeff cut his teeth working with father, Joe DeFranco, installing underground utilities. Jeff went on and acquired an extensive background in biochemistry while obtaining his Bachelor of Science degree at Geneseo State University. He was highly decorated during his collegiate stint for accomplishments in the sciences, including organic chemistry, biology, and physiology not to mention memorizing the periodic table of elements. As a certified trainer and aspiring physician, despite his acceptance into medical school, DeFranco decided to utilize his degree in a non-traditional fashion. He continued his expansion and exploration in the chemical and coating arena. This has allowed him to interface with highly educated professionals at the apex of their career industry. NACE Level III certified coating specifiers, engineers, chemists, industrial hygienists, and client HSE personnel all converse with DeFranco. DeFranco was first a field general installing coatings to generate revenue for his self-paid from Geneseo State University. With over three decades of application experience combined with his knowledge of chemical composition of the coatings, is what affords DeFranco the opportunity to alter coating systems on the fly. These customizations of the products have opened up markets by the ability to accommodate short installation windows and demanding expectations of coating performance.

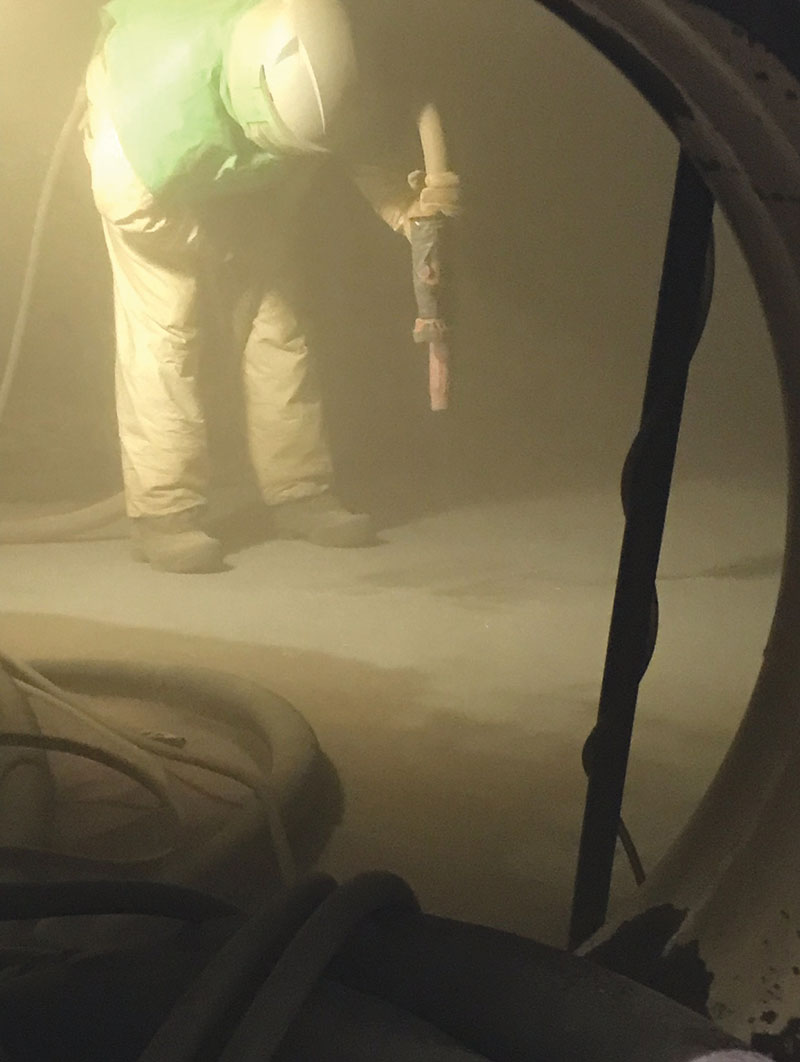

space regulations. NICI blasting to satisfy surface

preparation requirements in accordance with API

standards for 10-year reinstatement.

DeFranco is a certified NYS coach and natural born leader building his senior leadership installation team over decades. The latest acquisition to the NICI team was Jeff’s son, Nick DeFranco, who also worked alongside his father at NICI from a young age. Nick continued his education at John Carroll University as one of six graduates to obtain a B.S. degree in Economics and achieving Dean List’s status while playing football for the Blue Streaks. He decided to join NICI full time as VP of operations despite having many post college career options as he was a highly decorated student-athlete. Nick brings to the team energetic concepts that has earned respect amongst his coworkers and industry affiliates. While Jeff explores new markets and expansion, Nick brings the horsepower and his workforce to the table to accomplish the company goals. This father and son duo work together hand in hand daily to unify the marketing and sales aspect of the company with the day to day operations of the installation team. This uniquity provides clients with a simple but refreshing experience that they receive exactly what they were sold.

NICI is a one-of-a-kind company with the ability to offer several specialized installation divisions including: high performance floor coatings, roofing and waterproofing, architectural preparation and coating, concrete restoration, trench drain engineering and installation, API certified metal repairs and inspection, petroleum tank liners and coating, lead abatement, as well as structural steel sandblasting and coating. Clients are offered a turn-key approach with all aspects of their project from start to finish–specified, managed and installed by NICI. All aspects of the project are accomplished utilizing NICI’s OSHA certified and qualified personnel who uphold the highest safety culture and good manufacturing practices.

NICI services numerous food, beverage, and manufacturing companies throughout the northeast responsible for producing your everyday commodities. Under the company’s “NICI Care Maintenance Program,” clients can rest assured their facility remains at the highest level of safety and sanitation within a reasonable budget in compliance with USDA, FDA, and internal quality control audits. The NICI team is trained on food safety and good manufacturing practices. The staff has the ability to interpret auditor’s findings and immediately propose corrective actions to remediate the infractions. NICI has a strict code of conduct, including non-disclosure and confidentiality agreements to provide each client peace of mind ensuring their issues will be resolved in a professional manner.

Recently, the NICI team was called from one of many petroleum clients who had the need for a cyclical 10-year inspection on a million gallon tank. After 10 years in service, several variables need to be considered to determine if the tank’s integrity was sound and ensure there are no leaks to the surrounding environment. The petroleum clients must maintain a pristine environment adjacent to their tank fields to avoid costly fines and to ensure product is able to be moved in the most efficient way possible. Clients solicit NICI because of their history of performance on these high-profile types of projects with no room for error. NICI’s turn-key approach allows for one point of contact throughout the entire process which is unique in the industry as highlighted below.

The project entailed an extensive interior liner installation on a million gallon petroleum tank complete with an engineer evaluation and recommendation, sandblasting for inspection, internal Non-Destructive Examination (NDE) by engineers and a report of required API repairs, welding in accordance with AWS Code and ASME standards, near white metal sandblast, installation of a multi-layer high performance tank liner, and closing out with a NACE Level III inspection and holiday spark test, all under one contract held by NICI. The team encountered subzero temperatures and snowy conditions beyond what is typical for the Northeast this time of year. DeFranco reacted immediately to develop an alternate system with his team of engineers and specifiers to develop a low temperature coating system that would cure under these conditions. In addition to the coatings, forced-cure heating and exhaust ventilation in the million gallon tank had to be engineered to ensure proper performance.

Despite the subzero temperatures, the NICI team was outfitted with the appropriate cold weather gear and persevered to ensure their client’s needs were met as they always commit to. Upon completion of the project, the liner was inspected by a NACE Level III corrosion expert and was found to be at or above the manufacturer’s recommendations which provided the client a 10-year reinstatement certification allowing their continued production with peace of mind.

Another recent project involved a client in the food and beverage industry that needed to have several repairs completed in an area of the floor in their facility during operation. This offers a unique challenge as the repairs had to be completed while the adjacent areas of the plant remained in production. NICI’s extensive experience with it’s talented team of field generals and educated safety directors, engineering staff, and project managers were able to provide a solution to this challenging project. On this particular project, hermetically-sealed containment was erected, negative air flow engineered, products specified with zero VOC while meeting USDA requirements to ensure installation could be accomplished while the client continues to produce. NICI staff worked longer shifts and odd hours to return the areas in need of repair to full service in the shortest time window possible. Again, another example of how NICI delivers solutions to fulfill client specific needs.

NICI leads the industry in safety with a staffed safety director A.S. OS&H, 30-hour OSHA-certified team supervisors, site-specific safety plan, with training on a per project basis. This ensures the safety not only of DeFranco’s valued teammates but also the client’s employees and associates.

Jeff DeFranco, has deep relationships with several business owners and understands the necessity to minimize lost production in any business. He said, “The majority of our clients are in production around the clock on a yearly basis with minimal shutdowns. This necessitates in-production installation by our highly sophisticated team that no other company in the industry can match. This is accomplished through our ability to ‘melt into’ the everyday operation of our clients.”

NY State Industrial Coatings leaves no doubt with their proven track record of mitigating risk and ability to provide clients across the Northeast with industry leading service.

Sign up is quick, easy, & FREE.